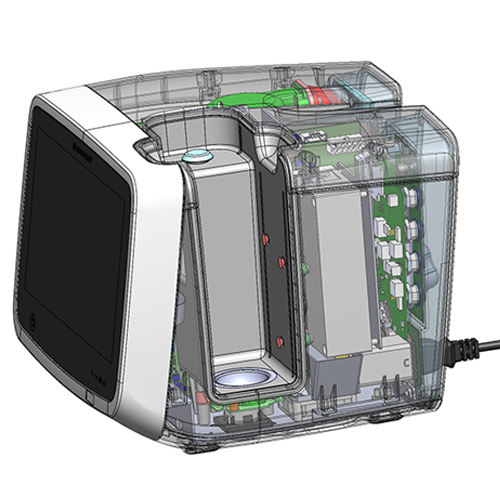

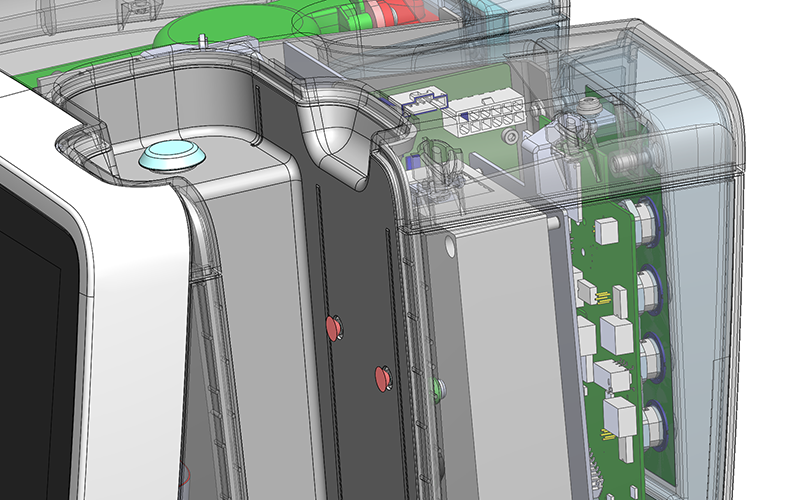

Before a single component is crafted, we dive deep into understanding your needs by asking: “What is the ultimate goal of this prototype?” Our prototyping capabilities are extensive, spanning everything from fast 3D printing for early-stage exploration to advanced CNC milling for critical, sealed designs. We recognize that a prototype for a pitch deck differs significantly from one for comprehensive durability testing. Our focus is always on providing the appropriate level of prototype fidelity required to equip you with the data essential for your success.

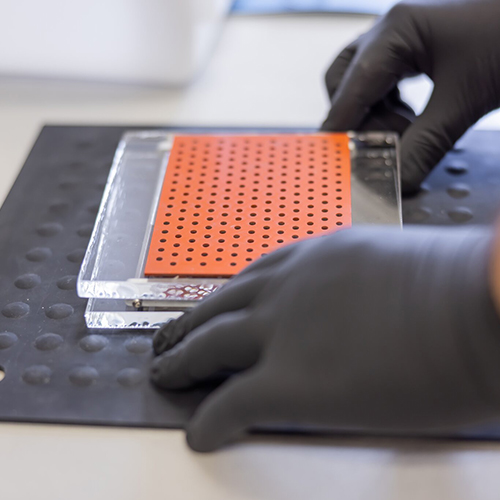

We view prototyping as a dynamic tool for discovery when paired with theory. We believe in the power of “thinking through making,” where each iteration serves as a tangible exploration of design possibilities. Our mechanical prototype development expertise spans 3D printing, CNC machining, bonding, and more, focusing on selecting the right materials and approach based on project needs.

We use a wide range of rapid prototyping technologies to quickly build your prototypes, enabling optimization and early detection of design flaws.

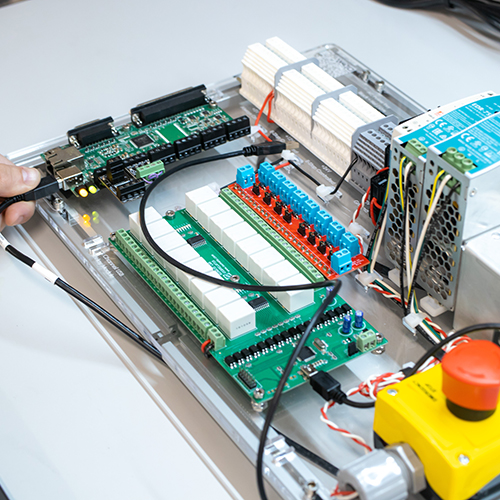

We use embedded systems to rapidly integrate and test the core technologies for the final product. By focusing on essential components like motors, memory, and microcontrollers, we make the prototype come to life, demonstrating its core functionality in a real-world context.

Our bonding and assembly capabilities create durable mechanical systems. Leveraging our retinue of bonding equipment, we can precisely bond a wide variety of materials, ensuring solid connections. We also incorporate design for assembly to streamline the process and reduce assembly time.

Our hardware and software engineers collaborate closely with the mechanical team from the start. Guided by the evolving mechanical design, we integrate necessary sensing and actuation to bring the product’s intended actions to life. Simultaneously, the mechanical team works within crucial constraints like size, space, movement limitations, and connectivity needs, which directly influence our electronic architecture. This close collaboration ensures that the developing prototype achieves its functional goals within the physical boundaries of the intended final product, paving the way for seamless product development.

NextGen Jane, a women’s health innovator, was looking for a reliable method to transport menstrual fluid samples from users’ homes to their lab for crucial analysis of conditions like endometriosis. We partnered with them to design and engineer a custom, manufacturable sample collection and transportation device. Beyond design, we established a small-scale production line at their lab, empowering their team to independently produce thousands of devices annually.

Fill out the form below and someone from our team will be in touch with you shortly.