We excel at developing cutting-edge products and instruments that seamlessly integrate mechanical and embedded electrical elements. With a team of engineers motivated not only by technical challenge but also by the drive to contribute to a greener future, we turn complex concepts into tangible, impactful solutions.

Our expertise in the thermal and fluid management and packaging of energy storage systems ensures optimal cooling and performance for large-scale energy storage projects. This enables the efficient storage and utilization of renewable energy.

By leveraging our expertise in thermal and fluid analysis, we create innovative prototypes and models that maximize energy efficiency in water heating systems, significantly reducing energy consumption.

We support greentech ventures that incorporate biological components, developing integrated instruments that seamlessly combine mechanical, electrical, and analytical elements for improved environmental monitoring and research.

We build smart, integrated products designed for challenging outdoor and industrial applications, ensuring all mechanical, electronic, and fluid systems work together in perfect harmony.

Greentech Expertise

Our team is uniquely equipped to engineer products that combine mechanical and embedded electrical components. This consolidated design approach is essential for sophisticated greentech projects that demand efficient and reliable integration of various technologies.

Utilizing a variety of rapid prototyping tools, we iterate quickly to evolve designs. We have the capability to manufacture parts in-house using technologies like CNC milling, turning, and laser cutting, in addition to advanced 3D printing techniques. We then assemble and test these parts with our robust plastic bonding infrastructure, which includes diffusion bonders, ultrasonic and laser welders, UV gluing, and solvent bonding. This integrated approach ensures that thermal, fluid, and electromechanical systems are rigorously tested and refined before moving to full-scale production.

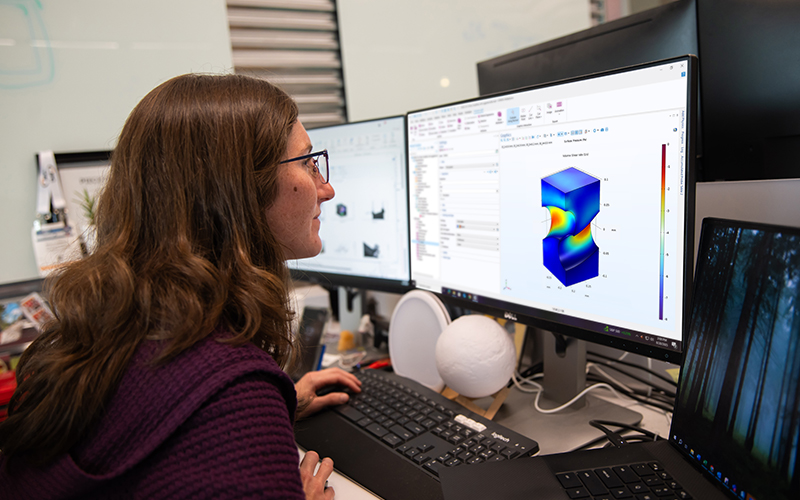

Comprehensive thermal and fluidic analysis capabilities underpin our hardware solutions. These expertise areas are particularly crucial for energy storage systems and high-efficiency water heating projects, where precise control over temperature and fluid flow is critical to system performance.

Fill out the form below and someone from our team will be in touch with you shortly.