Our Design for Manufacturing (DFM) approach leverages our team’s expertise in mechanical and electrical engineering by translating concepts into tangible, real-world products. We plan for manufacturing from day one, solving challenges throughout the entire process from prototype to production. We do this by considering factors like performance, affordability, and simplicity from the start. We’ve also brought production-level prototyping capabilities in-house, allowing us to create prototypes that accurately represent final manufacturing methods. This significantly reduces both technology and schedule risks by enabling us to move directly to the production-intent stage.

We understand that selecting the right materials is important for ensuring the safety, durability, and performance of your product. With our experience across a diverse range of processes, we’re always considering the best fit for your specific needs.

Engineer precision for intricate high-volume components and specialized low-volume parts, optimizing tooling longevity and part consistency.

Design strong and cost-effective enclosures and structural components that reduce waste and assembly steps.

Craft lightweight, robust enclosures and internal structures using structural foam, offering excellent strength-to-weight ratios and design flexibility.

Achieve ultra-high precision and tight tolerances for critical components with complex geometries, ensuring exacting performance requirements.

Develop robust, integrated forms with high strength and complex internal features, reducing part count and simplifying assembly.

Create custom profiles with consistent cross-sections and integrated functionality, ideal for structural elements or specialized conduits.

Deliver cost-effective solutions from large-format housings and protective covers with complex shapes to custom packaging for single-use disposables.

Integrate embedded software and hardware to bring advanced functionality and optimal performance to your product.

We streamline production by providing the right level of detail for your project, including tolerance stack-up evaluations, precise GD&T drawing packages when necessary, along with clear work instructions and accurate BOMs that account for strategic sourcing. By prioritizing Design for Assemblability (DFA), we reduce part counts and simplify assembly, while strategic wire routing enhances both efficiency and reliability.

Our embedded systems team complements our mechanical expertise by integrating DFM principles into the electronic and software aspects of product development, ensuring seamless and scalable production.

Our PCBA layout expertise optimizes component placement, signal integrity, and overall board manufacturability. We also specialize in PCB stack-up optimization for mass production, collaborating with fabrication and assembly partners to meet your needs.

An important part of our design process is component selection, where we prioritize multi-sourcing to mitigate supply chain risks and ensure consistent component availability for high-volume production.

Our Design for Testing (DFT) approach strategically incorporates test points and software interfaces for in-line and end-of-line testing. We help ensure a smooth transition to production by leveraging our low-volume capabilities internally and high-volume capabilities within Re:Build Manufacturing.

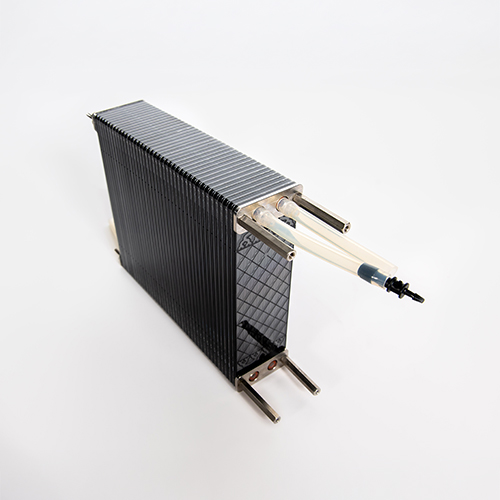

We partnered with a biotech firm to scale their single-channel microfluidic cartridge into a high-throughput manufacturing process for generating platelet-like cells. This project included redesigning the device for moldability, creating comprehensive drawing packages and assembly instructions, and helping to develop a robust inspection process to ensure transfusion-grade quality. These efforts enabled the transition to a multi-channel consumable and the automated equipment needed to produce large-scale quantities.

Fill out the form below and someone from our team will be in touch with you shortly.