Cumulus was looking to develop a cold brew coffee experience with a machine that could deliver high-quality, nitro-infused cold brew on demand. While Cumulus had started the journey with another firm, they encountered key development challenges. They sought a new partner who could bring a more rigorous, scientific methodology to the project, and that’s when they turned to Re:Build Fikst. What began as a small project to design the consumable aluminum coffee canisters quickly grew in scope, leading Re:Build Fikst to design the entire appliance and osmosis system. We leveraged our expertise to solve complex fluid dynamics, and create a system to ensure the cold brew was both delicious and consistent.

The development of the Cumulus cold brew machine involved overcoming several significant challenges, starting with the complex task of replicating the signature nitro mouthfeel. This required careful control over bubble size. Rather than relying on a trial-and-error method, our team applied a first-principles engineering approach to understand the fundamental physics of bubble creation, enabling us to meticulously control the process. We also faced the engineering challenge of integrating complex components, especially the nitro infusion technology, within the machine’s tight industrial design constraints.

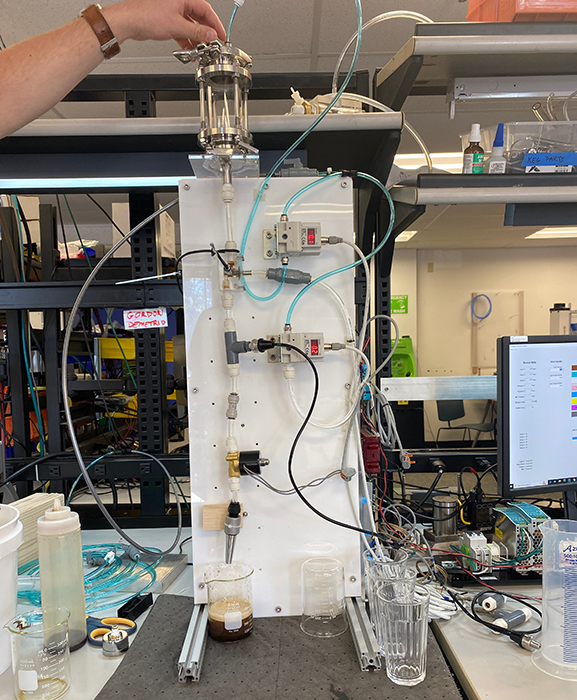

Our team designed and implemented a comprehensive data acquisition system using cameras, pressure, and temperature sensors to analyze bubble formation. This allowed us to understand the relationship between process parameters and bubble size, enabling the development of a controlled system for consistently producing the ideal microbubbles for the signature nitro mouthfeel.

An important part of the process was scientifically evaluating and building a system for concentrating coffee for the machine’s capsules, ultimately determining the most effective method between forward and reverse osmosis. We carefully designed and constructed a bench-sized experimental concentration system to evaluate forward osmosis, running it in parallel with another company’s reverse osmosis system. In collaboration with Cumulus’s Founder, we conducted side-by-side taste tests to determine the optimal method for preserving coffee flavor and quality.

Additionally, we provided significant support for the detailed design and manufacturing of the consumable aluminum capsules. This included multiple trips to contract manufacturers in China to troubleshoot production issues live with their teams, ensuring the highest quality control and successful product realization.

Image © Cumulus

Our work delivered several significant results and impacts:

Precise control over bubble formation allowed for reliable, on-demand nitro cold brew with the desired mouthfeel and cascading effect.

The side-by-side comparison of concentration methods provided Cumulus with the data needed to make an informed decision about their production process.

Our data-driven approach to problem-solving accelerated development, helping Cumulus avoid the pitfalls of trial-and-error.

Ultimately, our contributions helped Cumulus bring a high-quality, innovative product to market.

Insert customer testimonial quote here.

– Author

Image © Cumulus

Fill out the form below and someone from the Re:Build Fikst team will be in touch with you shortly.