We don’t just design products; we engineer solutions for the most challenging technical hurdles. We specialize in the early-stage exploration of product development, where scientific innovation meets engineering rigor. We bridge the gap between groundbreaking concepts and market-ready products, ensuring your technology is not only feasible but also repeatable and reliable. We’re not a prototype shop, but a partner in your journey, offering expertise from initial concept exploration to low-volume production, with a focus on deep technical understanding and robust execution.

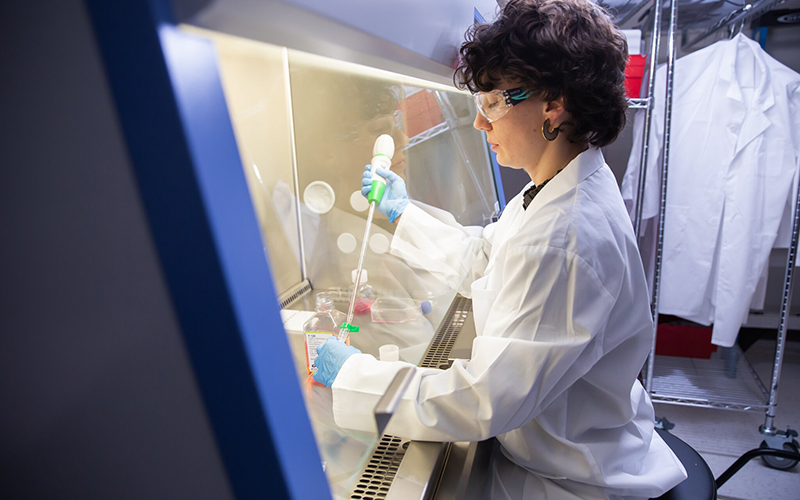

We combine scientific validation with creative exploration, transforming lab discoveries into robust, repeatable systems. We build prototypes with the right fidelity for each stage, starting with rough models to quickly test and prove core concepts. As development progresses, we increase fidelity as needed to ensure the technology’s core science is proven, not just theorized.

Our product development approach combines deep technical expertise with thoughtful design considerations. We guide you through every stage, from concept refinement to design for manufacturing. Whether you need to refine an existing product or develop a new one from scratch, we provide comprehensive engineering and design support to bring your vision to life.

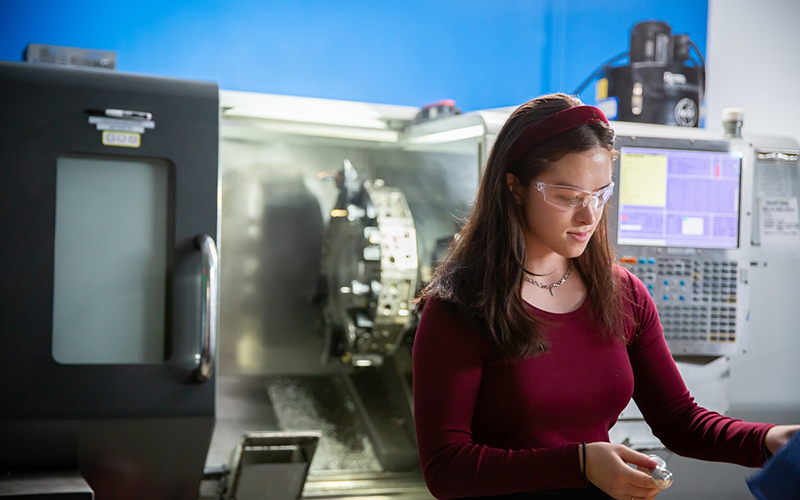

We begin every prototype build by clearly defining its purpose. Our approach is backed by a full arsenal of equipment, from 3D printers for rapid iteration to CNC mills for creating hermetically sealed, autoclavable systems. We understand the difference between a prototype for investor presentations and one for rigorous lifecycle testing. Our goal is to provide the right fidelity of prototype at every stage, ensuring you get the data you need to move forward confidently.

From the very first prototype, we are already thinking about manufacturability. We’ve helped clients successfully transition from lab-scale prototypes to high-volume production, ensuring a smooth and efficient process. We specialize in designing products for a wide range of manufacturing processes, from custom silicone gaskets to complex fluidic systems.

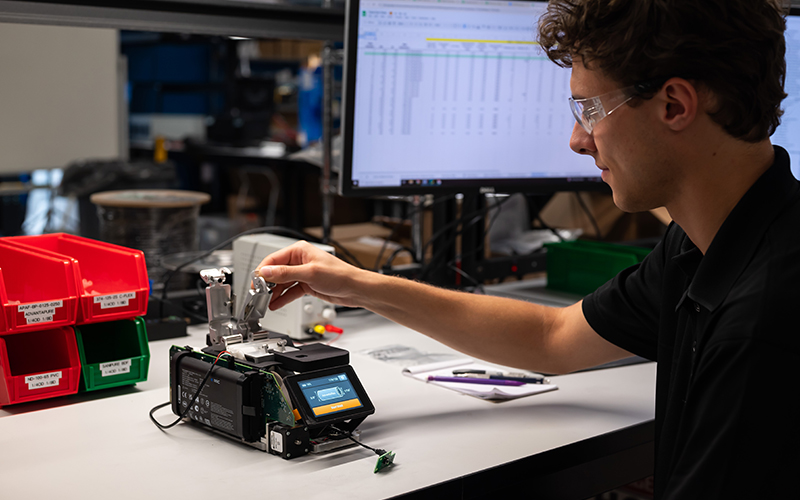

We’ve built automated test stands for everything from complex biological instruments to wine dispensing systems. We go beyond basic testing, integrating data acquisition, video analysis, and custom dashboards to provide real-time insights. We’ve helped clients run 10,000-cycle tests, capturing every data point and video frame. We don’t just test; we engineer testing solutions.

High-volume contract manufacturers are not often well equipped for low-volume production runs to support initial sales, product testing, clinical trials, or market acceptance efforts. We specialize in working with companies looking for low-volume initial production, providing the perfect bridge between beta prototyping and full-scale manufacturing. Our adaptable manufacturing approach helps minimize risks during the transition from engineering prototypes to low-volume production.

Fill out the form below and someone from our team will be in touch with you shortly.